High-performance fibre and high-quality yarn trends in the vibrant Chinese market

Major trends in China

Fibre is at the source of the textile industry chain, and its development is highly relevant to the quality of downstream fabric products, printing and dyeing, and apparel products.

As China aims to transform its industry and shift more of its resources into higher value-added manufacturing, chemical fibre not only satisfies the needs of textile industry in terms of volume, but is also drives the development of the textile industry in terms of technology, fashion and sustainability. The chemical fibre industry offers the raw materials to build the foundation for the textile industry, adding value to the industry chain by initiating the development of high-end new fibre materials, intelligent digitalisation and low-carbon green production.

Cinte Techtextil China 2022 will be held at the Shanghai New International Expo Centre from 6 – 8 September, offering the perfect business platform for textile fibre and yarn suppliers to reach relevant customers and expand their business opportunities.

Innovation and development of textile fibre industry in China

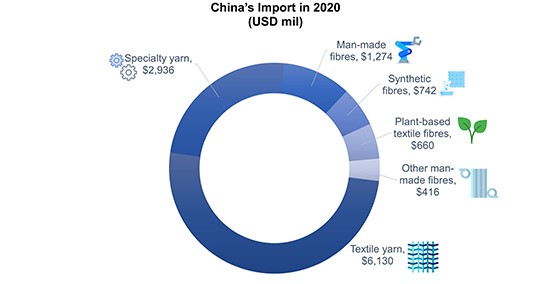

According to the United Nations COMTRADE database on international trade, in 2020, China imported more than USD 3 billion of fibre products and more than USD 9 billion of yarn products. In terms of exports, chemical fibre accounted for more than 84% of China’s total textile fibre processing output, which is more than 70% of the world’s total, further establishing the country’s key role in the global fibre industry. In addition to apparel and home textiles, it is also widely used in aerospace, marine engineering and other fields.

With the advancement in wind power, photovoltaics and the transportation industry, the demand for high-performance fibre products such as carbon fibre will increase drastically. It is necessary to optimize and improve the supply chain of high-quality and high-performance fibre products to lead a strategic enhancement of the entire textile industry from the source.

Digitalisation and automation lead the way

The new plan for China’s economic development involves tremendous investments in high-tech manufacturing to decrease the country’s share in lower value-added sectors, and enable China’s movement into higher value-added production. With increased investments in R&D and technology, China has managed to take a giant leap forward following its Industry 4.0 plan with the aim to become a global leader in the sectors of tomorrow.

“Fujian QL Metal Fiber focuses on producing metal fibre and its technical textile applications. We are showcasing the stainless steel series of fibres and yarns… our technical textile customer base the manufacturers from the smart fabrics industry. We have met some of the clients who are aiming to find new materials. It is the first time we exhibit at this fair as our business is closely matched with it, so that’s why we hope to promote the brand here. We will definitely exhibit again in the future.”

Ms Rachel, Sales Director, Fujian QL Metal Fiber Co Ltd – Cinte Techtextil China 2021 exhibitor

Smarter and greener production go hand-in-hand

The chemical fibre industry is undergoing transformation towards smarter and greener production. Significant progress has been made in green development, branding and standardisation. Fibre trends in China call for a trusted platform for traceable green fibre products that are certified for energy saving, emission reduction, recyclability and biodegradability.

Currently the industry’s carbon emissions account for nearly 10% of the total, and as the awareness of the importance of sustainability has also been rising among consumers, the situation is now changing with players throughout the supply chain, including yarn producers and textile manufacturers, channelling resources and efforts into addressing the problem.

“The market is paying more attention to environmental protection products. Every day we receive enquiries about special yarns for this. Our production is focused on technical yarns, such as for filtration as well as anti-bacterial properties, which is very important for the environment and the future for production… The Chinese market is a big opportunity for everybody, because every day the market is demanding more. The potential here is incredible.”

Mr Roberto Galante, Plant Manager, FMMG Technical Textiles (Suzhou) Co Ltd, China (Fil Man Made Group, Italy) – Cinte Techtextil China 2021 exhibitor

Post time: Dec-13-2021