factory Outlets for China Wear Resistant and Anti Slip Silicone Sleeve

Our solutions are broadly acknowledged and trustworthy by end users and might meet up with consistently transforming economic and social needs of factory Outlets for China Wear Resistant and Anti Slip Silicone Sleeve, We are looking forward to forming successful business relationship with new clients in the near future!

Our solutions are broadly acknowledged and trustworthy by end users and might meet up with consistently transforming economic and social needs of China Hydraulic Hose, Hose, We win many reliable customers by rich experience, advanced equipments, skilled teams, strict quality control and best service. We can guarantee all our items. Customers’ benefit and satisfaction are always our biggest goal. You should contact us. Give us a chance, provide you with a surprise.

Product Name Presol O R

Color Index Solvent Orange 107

Delivery Form Powder

CAS 185766-20-5

EINECS NO. —

Technical Properties:

Solvent Orange 107 is an orange dye with high color strength.

It has excellent heat resistance and light resistance, good migration resistance and high tinting strength with wide application.

Solvent Orange 107 is used for coloring for plastics, PS, ABS, PMMA, PC, PET, polymer, fiber. Solvent Orange 107 is recommended for polyester fiber.

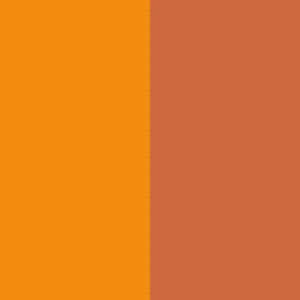

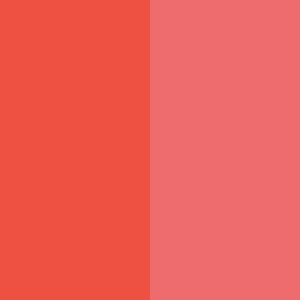

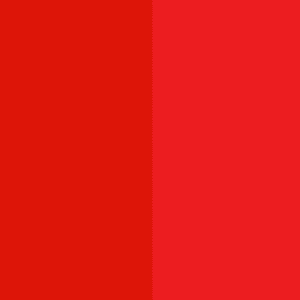

Color Shade:

Application: (“☆” Superior, “○” Applicable, “△” Not recommend)

|

PS |

HIPS |

ABS |

PC |

RPVC |

PMMA |

SAN |

AS |

PA6 |

PET |

|

☆ |

☆ |

☆ |

☆ |

△ |

☆ |

☆ |

○ |

△ |

☆ |

Also used in coloring of terylene fibre’s protoplasm.

Physical Properties

|

Density(g/cm3) |

Melting Point(℃) |

Light fastness (in PS) |

Recommended Dosage |

|

|

Transparent |

Nontransparent |

|||

|

1.74 |

224 |

7~8 |

0.025 |

0.05 |

Light Fastness: Consist of 1st to 8th grade, and the 8th grade is superior, the 1st grade is bad.

The heat resistance in PS can reach to 300℃

|

Water |

Acetone |

Benzyl alcohol |

Butyl acetate |

Ethanol |

Methyl methacrylate |

Methylene chloride |

Styrene (monomer) |

Xylene |

|

insoluble |

3.5 |

65 |

3.0 |

0.8 |

1.5 |

60 |

5.0 |

1.0 |

Degree of pigmentation: 0.05% dyes+0.1%titanium dioxide R

Note: The above information is provided as guidelines for your reference only. The accurate effects should base on the test results in laboratory.

———————————————————————————————————————————————————————————

Customer Notification

Applications

Presol Dyes are comprised with a wide rage of polymer soluble dyes which can be used for coloring a wide variety of plastics. They are normally used via masterbatches and add into fiber, film and other plastic products.

When using Presol Dyes into engineering plastics with strict processing requirements, such as ABS, PC, PMMA, PA, only specific products are recommended.

When using Presol Dyes into thermo-plastics, we suggest to mix and disperse the dyes sufficiently together with the right processing temperature to achieve better dissolution. In particular, when using high melting point products, such as Presol R.EG (Solven Red 135), a full dispersion and suitable processing temperature will contribute to a better coloration.

High performance Presol Dyes are complaint with the global regulations in below applications:

● Food packaging.

● Food-contacted application.

● Plastic toys.

QC and Certification

1) Powerful R&D strength makes our technique in a leading level, with standard QC system meet EU standard requirements.

2) We have ISO & SGS certificate. For those colorants for sensitive applications, such as food contact, toys etc., we can support with AP89-1, FDA, SVHC, and regulations according to EC Regulation 10/2011.

3) The regular tests involve Color Shade, Color Strength, Heat Resistance, Migration, Weather Fastness, FPV(Filter Pressure Value) and Dispersion etc.

- ● Color Shade test standard is according to EN BS14469-1 2004.

- ● Heat Resistance test standard is according to EN12877-2.

- ● Migration test standard is according to EN BS 14469-4.

- ● Dispersibility test standard is according to EN BS 13900-2, EN BS 13900-5 and EN BS 13900-6.

- ● Light/Weather Fastness test standard is according to DIN 53387/A.

Packing and Shipment

1) Regular Packings are in 25kgs paper drum, carton or bag. Products with low density will be packed into 10-20 kgs.

2) Mix and different products in ONE PCL, increase the working efficiency for customers.

3) Headquartered in Ningbo or Shanghai, both are large ports which are convenient for us provide logistics services.Our solutions are broadly acknowledged and trustworthy by end users and might meet up with consistently transforming economic and social needs of factory Outlets for China Wear Resistant and Anti Slip Silicone Sleeve, We are looking forward to forming successful business relationship with new clients in the near future!

factory Outlets for China Hydraulic Hose, Hose, We win many reliable customers by rich experience, advanced equipments, skilled teams, strict quality control and best service. We can guarantee all our items. Customers’ benefit and satisfaction are always our biggest goal. You should contact us. Give us a chance, provide you with a surprise.